|

Ningbo Power Hydraulic Motor Co., Ltd.

|

solenoid actuated poppet directional valves

| Payment Terms: | T/T |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

-Solenoid coil can be rotated through 90 °

-Individual electrical connection

-With protected hand override, optional

Features of solenoid actuated poppet directional valves :

-Direct actuated directional poppet valve, solenoid actuated

-Closed port is leak-free

-Switching is ensured even after long periods of being

under pressure

-Solenoid coil can be rotated by 90°

-Individual electrical connection

-With protected hand override, optional

Functional description of solenoid actuated poppet directional valves

General:

General:

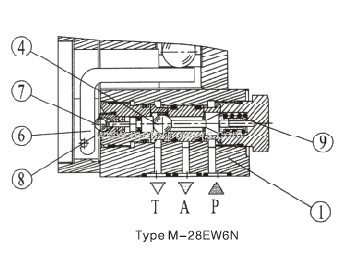

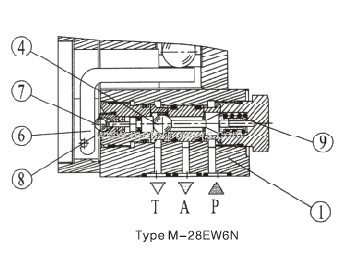

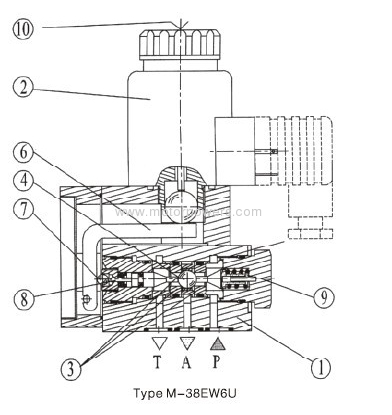

The 2 type M-.SEW directional valve is a solenoid actuated directional poppet valve. They control the start, stop and direction of a flow. They basically consist of a housing (1),the solenoids (2),the hardened valve. system (3) and the ball(s) (4) as the closing element.

Basic principle:

In the initial position the ball (4) is pressed onto the seat by the spring (9), and in the switched position by the solenoid (2).

The solenoid (2) force acts via the lever (6) and the ball (7) on the actuator pin (8), which sealed on two sides.

The chamber between the two sealing elements is connected with port P. The valve system (3) is thereby pressure balanced with regard to the actuating forces (solenoid or return spring). The valves can, therefore, be used up to a pressure of 63MPa.

Note:

The 3/2-way poppet valves have a "negative switching overlap".

Therefore, port T must always be connected. This means that during the witching procedure from the start of opening one valve seat to the closing of the other seat - all of the ports P-A-T are connected with each other. This, however, takes place in such a short space of time that in most applications it is irrelevant. The hand override (10) makes it possible to switch the valve without energizing the solenoids. Care has to be taken to ensure that the stated maximum flows are not exceeded! If necessary a cartridge throttle for flow limitation has to be fitted (see below).

Section 1 of poppet directional valves, solenoid actuated

Section 2 of poppet directional valves, solenoid actuated

Section 1 of poppet directional valves, solenoid actuated

Section 2 of poppet directional valves, solenoid actuated

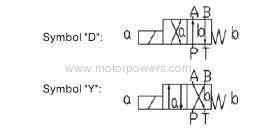

The following possibilities are obtainable via the seat orientation

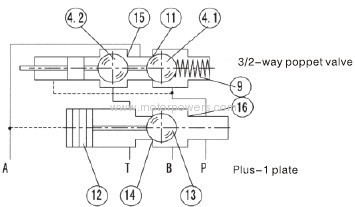

In conjunction with a sandwich plate, a plus-1 plate, under the 3/2-way poppet valve this valve can be used as 4/2-way poppet valve.

Function of the plus-1 plate:

Initial position:

The main valve is not actuated. The spring (9) holds the ball (4.1) on the seat (1i). Port F is closed and A is connected to T. In addition, a control line runs from A to the large area of the control spool (12), which is thus unloaded to tank. The pressure plied via P now moves the ball (13) onto seat (14).Thus, P is connected to B and A to T.

Translation position:

When the main valve is operated, the ball (4.2) is pushed against the spring (9) and then pressed onto the seat (15).Port T is then blocked, P,A and B are connected to each other for a short time.

Switched position:

P is connected to A. As the pump pressure acts via A on the large area of the control spool (12), ball (13) is pushed onto seat (16).Thus, B is connected to T and P to A. Ball (13) in the plus-l plate has a "positive switching overlap". In order to avoid pressure intensification when single rod cylinders are used, the annulus area of the cylinder must be connected to A.

Due to the use of the plus-1 plate and the arrangement of the seats, the following combinations are possible:

Schematic illustration: innitial position

Section 3 of poppet directional valves, solenoid actuated

Cartridge throttle

Cartridge check valve

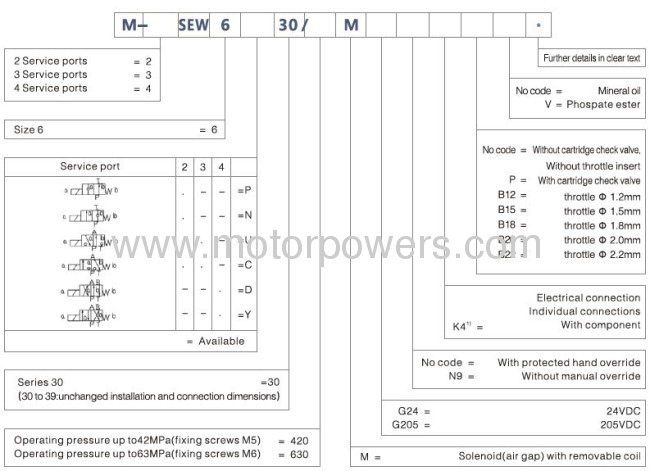

Ordering details of poppet directional valves with solenoid actuated

Technical data of solenoid actuated poppet directional valves

General

Installation | Optional |

Max. temperature range ℃ | -30~+50 |

2/2-way poppet valve kg | 1.5 |

3/2-way poppet valve kg | 1.5 |

4/2-way poppet valve kg | 2.3 |

Hydraulic data

Max. operating pressure (Mpa) | See table before |

Max. flow L/min | 25L/min |

Pressure Fluid Temperature range ℃ | -30~+80 |

Viscosity range mm²/s | 2.8~500(for 2/2-way poppet valve 2.8~380) |

Degree of contamination | Max. permissible degree of contamination of the fluid is to NAS 1638,class 9.β10≥75 |

Electrical data

Voltage type | DC Voltage | AC Voltage |

Available voltage V | 12\24\42\96\110\205\220 | Only possible via rectifier |

Voltage tolerance (nominal voltage) % | ±10 | |

Power consumption W | 30 | |

Duty | 100% | |

Switching time to ISO 6403 | See the table below | |

Switching frequency cycles /h | 15,000 | |

Protection to DIN 40050 | IP65 | |

Max. Coil temperature ℃ | To 150 |

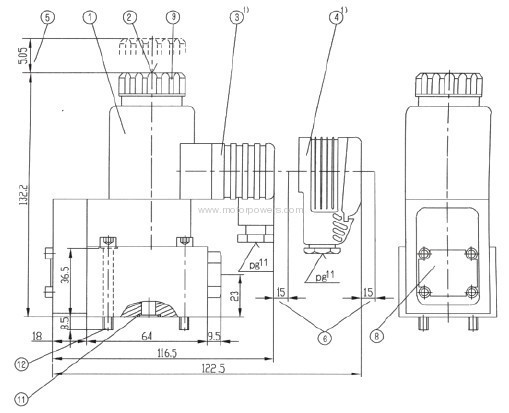

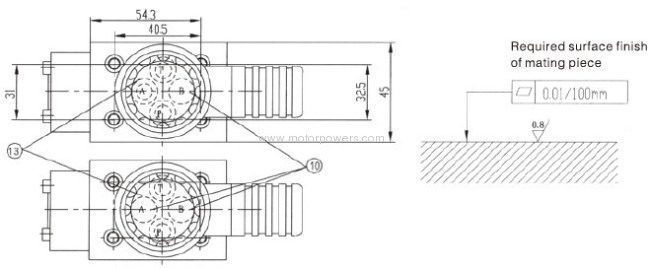

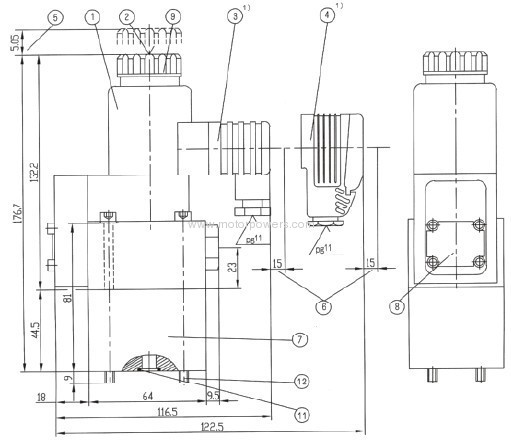

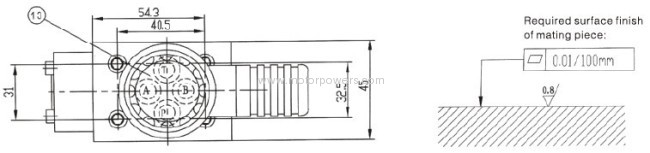

Unit dimensions (dimensions in mm)

1st picture of 2/2-,3/2-way poppet valve

2nd picture of 2/2-,3/2-way poppet valve

1st picture of 4/2-way poppet valve

2nd picture of 4/2-way poppet valve

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Directional Valves

Directional Solenoid Valve

Solenoid Operated Directional Valve

Hydraulic Solenoid Directional Valve

Solenoid Valves

Pilot Solenoid Valves

More>>