|

Ningbo Power Hydraulic Motor Co., Ltd.

|

direct operated pressure relief valve

| Price: | 10.0~100.0 USD |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

-For threaded connection

-For cartridge connection

. Sleeve with hexagon and protective cap

. Rotary knob

. Lockable rota

Feature of direct operated pressure relief:

-For subplate mounting

-For threaded connection

-For cartridge connection

. Sleeve with hexagon and protective cap

. Rotary knob

. Lockable rotary knob with scale

Functional description of Pressure relief valve, direct operated

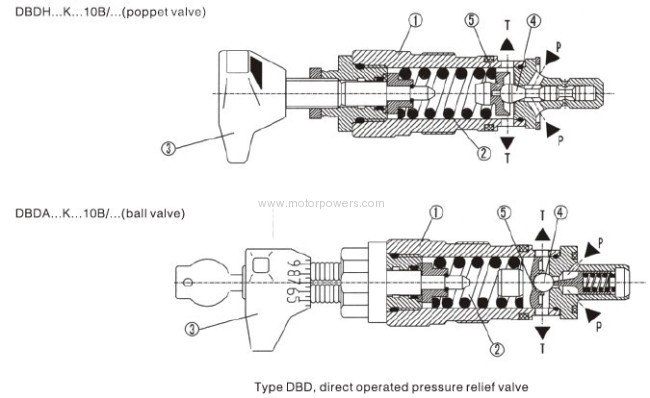

The DBD pressure relief valves are direct operated poppet valves. They are used to limit the pressure in a hydraulic system.

The valves mainly consist of sleeve (1), spring (2), poppet with damping spool (4) (pressure stages 2.5 to

40 MPa) or ball (4) (pressure stage 63 MPa) and adjustment element (3). The setting of the system pressure is infinitely variable via the adjustment element (3). The spring (2) pushes the poppet (4) onto the seat. The P channel is connected to the system. The pressure present in the system is applied to the poppet area (or ball).

lf the pressure in channel P rises above the valve set at the spring (2), the poppet (4) opens against the spring (2). Now pressure fluid flows form channel P into channel T. The stroke of the poppet (4) is limited by a pin. In order to maintain a good pressure settings over the entire pressure range the pressure range is split into 7 pressure stages. One pressure stage corresponds to a certain spring for a maximum operating pressure which may be set with it.

Section of direct operated pressure relief valve:

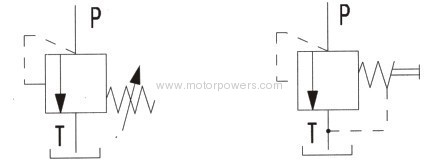

Symbol of direct operated pressure relief valve:

Ordering details:

Technical data:

Size | 6 | 8\10 | 15\20 | 25\30 | |

Max. operating pressure | Port P | 40 | 63 | 40 | 31.5 |

Port T | 31.5 | ||||

Max. flow L/min | 50 | 120 | 250 | 350 | |

Pressure Fluid | Mineral oil or Phospate ester | ||||

Temperature range ℃ | -30~+80 | ||||

Viscosity range mm²/s | 2.8~500 | ||||

Unit dimensions (dimensions in mm)

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Pressure Relief Valve

Pressure Operated Valve

Pressure Relief

Relief Valve

Operated Valve

Safety Relief Valve

More>>