|

Ningbo Power Hydraulic Motor Co., Ltd.

|

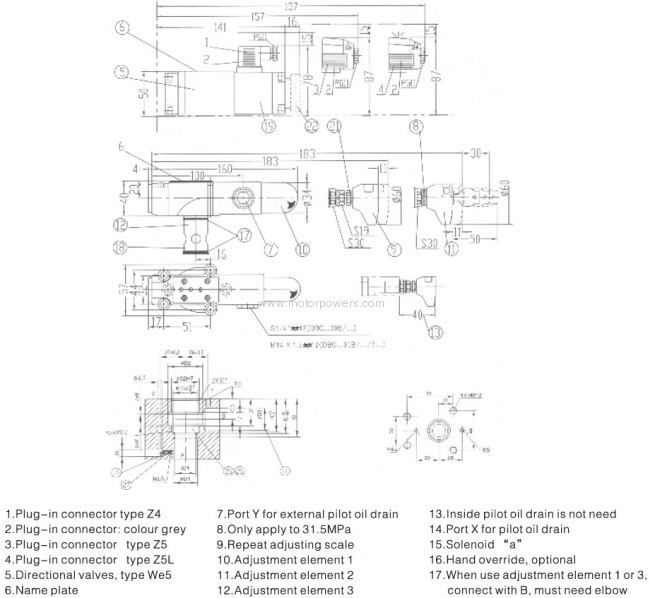

400 L/min Max. flow pilot operated pressure relief valve

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Types DB and DBW pressure valves are pilot operated pressure relief valves.

Very competitive price

Three adjustment elements

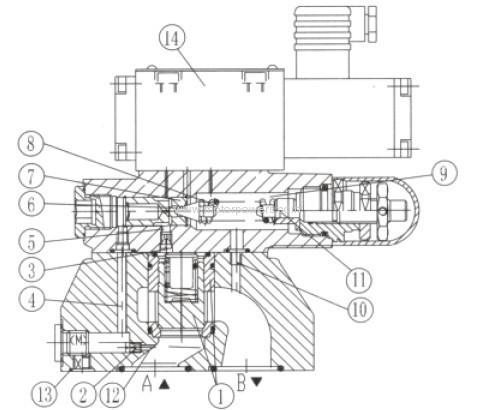

Section of type DBW...30B/

Features of Rexroth pilot operated pressure relief valve:

Features of Rexroth pilot operated pressure relief valve:

-Subplate mounting

-Pipe connection

-Insert connection

-Three adjustment elements:

. Rotary knob

. Hex. head screw with protective cap

. Lockable rotary knob with scale

-Solenoid operated unloading via a built-in directional spool valve

Types DB and DBW pressure valves are pilot operated pressure relief valves.

They are used for the limitation (DB) or limitation and solenoid actuated unloading (DBW) of the control pressure.

The pressure relief valves (DB) consist mainly of the main valve (1) with main spool assembly (3) and pilot operated valve (2) with pressure adjustment element.

Pressure relief valve type DB:

The pressure presents in port A acts on the main spool (3) At the same time pressure is applied via the control lines (6) and (7), which are fitted with orifices (4) and (5), on the spring loaded side of the main spool (3) and at the poppet(8) in the pilot control valve (2). If the pressure in port A exceeds the value set at the spring (9), the poppet (8) opens against the spring (9).

Pressure relief valve type DB:

The pressure presents in port A acts on the main spool (3) At the same time pressure is applied via the control lines (6) and (7), which are fitted with orifices (4) and (5), on the spring loaded side of the main spool (3) and at the poppet(8) in the pilot control valve (2). If the pressure in port A exceeds the value set at the spring (9), the poppet (8) opens against the spring (9).

The signal for this comes internally via the control lines (10) and (6) from port A. The pressure fluid on the spring loaded side of the main spool (3) now flows via the control line (7), orifice bore (11) and poppet (8) into the spring chamber (12). In type DB...30/... it flows internally via the control line (13) to tank, or in type DB..30/..Y.. externally via the port Y. Due to the orifices (4) and (5) a pressure drop occurs at the main spool (3), the connection from port A to port B is open. Now the pressure fluid flows from port A to port B while maintaining the value set operating pressure.

The pressure relief valve may be unloaded or switched over to a different pressure (second pressure stage) via port "X" (15).

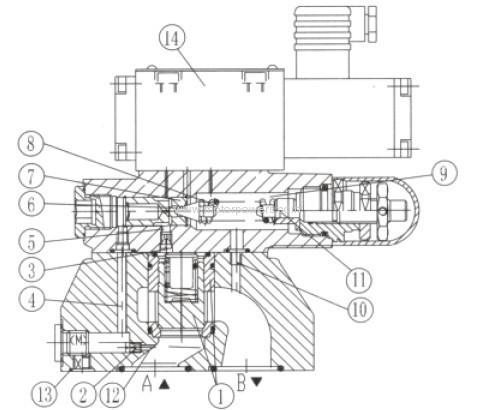

Oil control forms of graphlic symbols

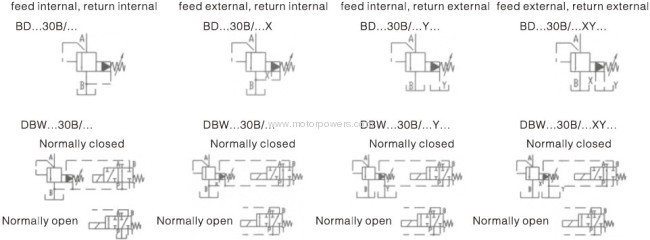

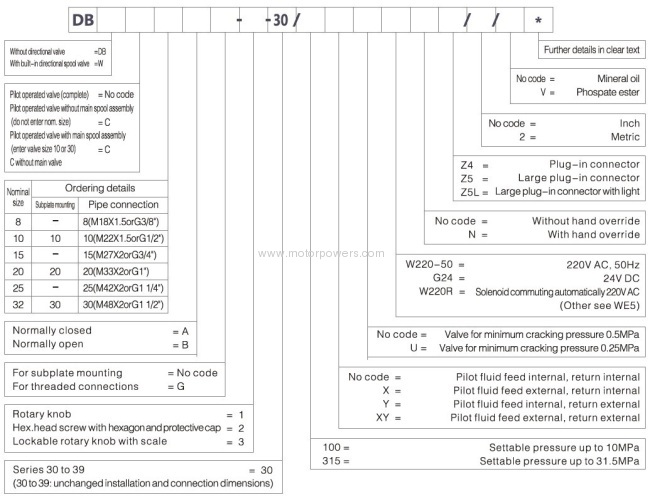

Ordering datails of400 L/min Max. flow pilot operated pressure relief valve

Technical data of 400 L/min Max. flow pilot operated pressure relief valve:

Size | 8 | 10 | 15 | 20 | 25 | 30 | ||

Max. flow L/min | Threaded connections | 100 | 200 | 200 | 400 | 400 | 600 | |

subplate mounting | - | 200 | - | 400 | - | 600 | ||

Operating pressure port A B X (Mpa) | To 31.5 | |||||||

Back pressure (Mpa) | DB | To 31.5 | ||||||

DBW | To 6 | |||||||

Min. setting pressure (Mpa) | Flow dependent | |||||||

Max. setting pressure (Mpa) | To 10 or 31.5 | |||||||

Pressure Fluid | Mineral oil or Phospate ester | |||||||

Viscosity range mm²/s | 10~800 | |||||||

Temperature range ℃ | -30~+80 | |||||||

Characteristic of solenoid valve | See type WE5 | |||||||

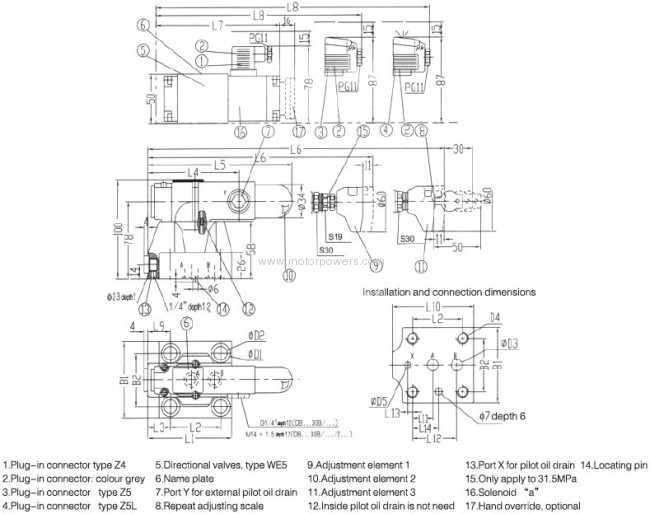

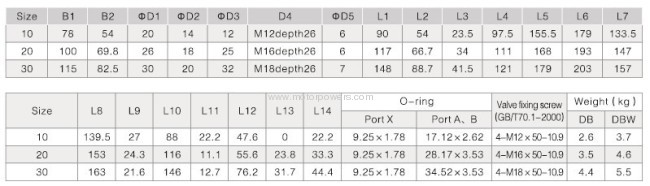

Unit dimensions (dimensions in mm)

Subplate mounting:

Port Size 1

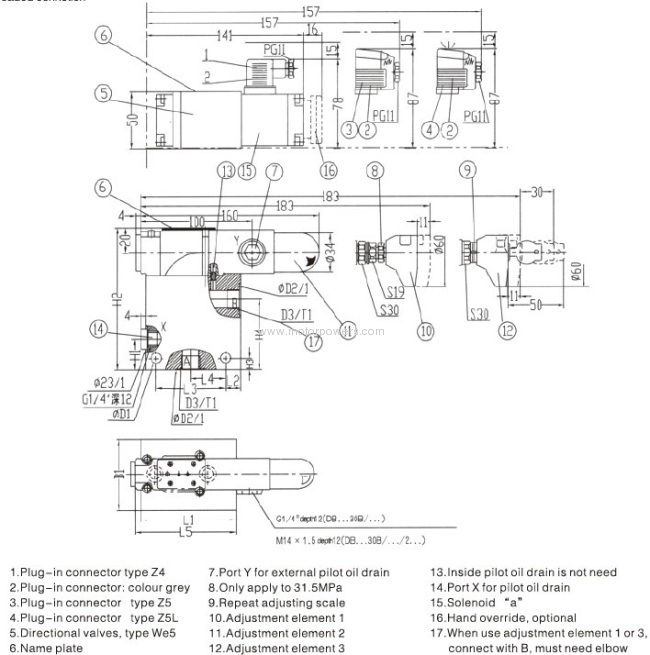

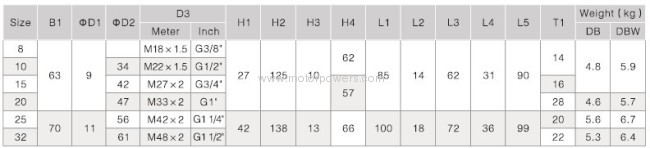

Threaded connection

Port Size 2

Cartridge connection:

1. Low noise design can ensure the stability

2. Under the electronic control which can ensure pump and hydraulic system unloading or keep rated pressure.

3. Combine the remote valve,can actualize the 2-3 degree pressure control.

Ningbo Power has 10 sets of imported CNC machPowerng center and 5 sets of imported lath turning machPowerng center and digital control lathes, 5 sets of domestic digital control lathes and CNC multi-head drilling machine. Due to the strong process capability, the quality of main parts processed by CNC can be guaranteed well.

Not only the main parts of Power products used high-grade alloy steel material like 20CrMnTi, 42CrMo, but also adopted advanced heat treatment technology including treatment of carbon penetration, quenching, salt bath and nitrogen treatment to promise the product quality. The key parts such as screw cartridge valves, sealing, and screw bolts all were imported from USA, Germany, Italy, France and Taiwan...

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Max Min Thermometer

Pressure Relief Valve

Pressure Operated Valve

Pressure Relief

Pilot Valve

Relief Valve

More>>